The basic raw materials of carbon paste are composed of electric calcined anthracite coal, calcined petroleum coke, carbon anode scrap and coal tar pitch.

In addition to coal tar pitch, these raw materials are crushed and sieved into particles and powder, then mixed and heated according to a certain proportion, and finally coal tar pitch is added, in which the powder proportion is usually controlled at about 40%.

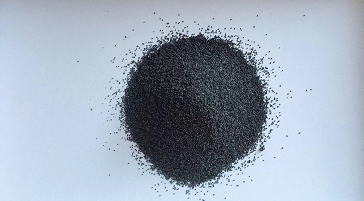

Generally, calcined petroleum coke particles above 1mm are used in foundry and iron and steel metallurgy industries, and calcined petroleum coke powder is used as raw material of carbon paste.

The ash content and volatile content of calcined petroleum coke powder are relatively low, and the sulfur content is generally 1.5-2.5%. These parameters are OK for carbon paste.