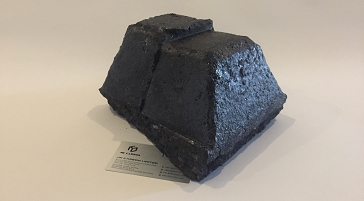

Carbon electrode paste is used as self-baking electrodes for submerged arc furnaces,it’s a kind of carbon products,consisting of ECA,CPC and graphite powder,with the coal tar pitch as the binder,after the mold shaping.During the application,the paste will be put into the electrode casing from the top side,and the paste will be baked into an electrode finally,as the electrode casing drops down and the temperature comes to the high.The baked electrode will conduct the electricity and transforming the electricity to heat the materials via the ectrode peak in furnace.

The production process of carbon electrode paste is simpler than that of carbon anode for aluminum electrolysis, but its quality stability requirements are relatively high, mainly due to two reasons:

On the one hand, in terms of the ingredient and ratio of carbon electrode paste, there are big difference between the manufacturers, so the quality characteristics of the carbon electrode paste produced will naturally have significant differences.

On the other hand, the downstream factories of carbon electrode pastes vary are different, and their needed characteristics and other requirements for carbon electrode pastes are different. Therefore, those factories using carbon electrode pastes generally do not want to change their suppliers of carbon electrode pastes, unless there is a serious quality issue of the carbon electrode paste during use, especially there are such phenomena as too fast consumption, broken pole during use. That is to say, the quality of the carbon electrode paste is finally based on the results of the actual use effect, and the test results of each index parameter are merely necessary references.

For this reason, the cooperation between carbon electrode paste manufacturers and the users shows a long-term characteristic; in China, a structure of northern-southern zones has gradually formed on the production and use of carbon electrode paste: for carbon electrode paste manufacturers in northern China, their customers are basically limited to the northern region; likewise, the manufacturers of carbon electrode paste in southern China, their customers are limited to the southern regions.

The reason for this situation is based on the characteristics of the carbon electrode paste and the long-term cooperation between the manufacturers and the customers. Of course, the export of carbon electrode paste is quite different from the above situation—both the southern and northern manufacturers can export carbon electrode paste from the neighboring ports.

In recent years, the OEM cooperation model of carbon electrode paste has been developed. In order to stabilize the quality characteristics of carbon electrode paste and develop cooperative relations, exporters usually invest equity in the production lines and OEM production of carbon electrode paste.

After the end of the epidemic this year, our company carried out due diligence on the production line of carbon electrode paste in southern China and became a shareholder of the factory. While doing a good job in the domestic market, we also take this as the basis to actively expand the overseas market of carbon electrode paste.

Carbon electrode paste is used as self-baking electrodes for submerged arc furnaces,it’s a kind of carbon products,consisting of ECA,CPC and graphite powder,with the coal tar pitch as the binder,after the mold shaping.During the application,the paste will be put into the electrode casing from the top side,and the paste will be baked into an electrode finally,as the electrode casing drops down and the temperature comes to the high.The baked electrode will conduct the electricity and transforming the electricity to heat the materials via the ectrode peak in furnace.

The production process of carbon electrode paste is simpler than that of carbon anode for aluminum electrolysis, but its quality stability requirements are relatively high, mainly due to two reasons:

On the one hand, in terms of the ingredient and ratio of carbon electrode paste, there are big difference between the manufacturers, so the quality characteristics of the carbon electrode paste produced will naturally have significant differences.

On the other hand, the downstream factories of carbon electrode pastes vary are different, and their needed characteristics and other requirements for carbon electrode pastes are different. Therefore, those factories using carbon electrode pastes generally do not want to change their suppliers of carbon electrode pastes, unless there is a serious quality issue of the carbon electrode paste during use, especially there are such phenomena as too fast consumption, broken pole during use. That is to say, the quality of the carbon electrode paste is finally based on the results of the actual use effect, and the test results of each index parameter are merely necessary references.

For this reason, the cooperation between carbon electrode paste manufacturers and the users shows a long-term characteristic; in China, a structure of northern-southern zones has gradually formed on the production and use of carbon electrode paste: for carbon electrode paste manufacturers in northern China, their customers are basically limited to the northern region; likewise, the manufacturers of carbon electrode paste in southern China, their customers are limited to the southern regions.

The reason for this situation is based on the characteristics of the carbon electrode paste and the long-term cooperation between the manufacturers and the customers. Of course, the export of carbon electrode paste is quite different from the above situation—both the southern and northern manufacturers can export carbon electrode paste from the neighboring ports.

In recent years, the OEM cooperation model of carbon electrode paste has been developed. In order to stabilize the quality characteristics of carbon electrode paste and develop cooperative relations, exporters usually invest equity in the production lines and OEM production of carbon electrode paste.

After the end of the COVID-19 this year, our company carried out due diligence on the production line of carbon electrode paste in southern China and became a shareholder of the factory. While doing a good job in the domestic market, we also take this as the basis to actively expand the overseas market of carbon electrode paste.