Carbon Anode block after completing life cycle under the reduction pot cell is called Butts(used or spent anodes).The white layer over the butt is bath material.And you know this is called butt the spent Andoe but there is not a single dust particles of this butt unit is waste .every thing is recycled in operation and used again in the process.

This machine is called MFC THE MULTI FUNCTION CAR in aluminum smelter operation in anode Rodding department used for unloading of new rodded anodes and loading of spent anodes butts receive from reduction pot line cell under system through over head power and free conveyor.This stage were the cycle process of Rodding starts and end also.I am expert in operation of these all heavy machinery..

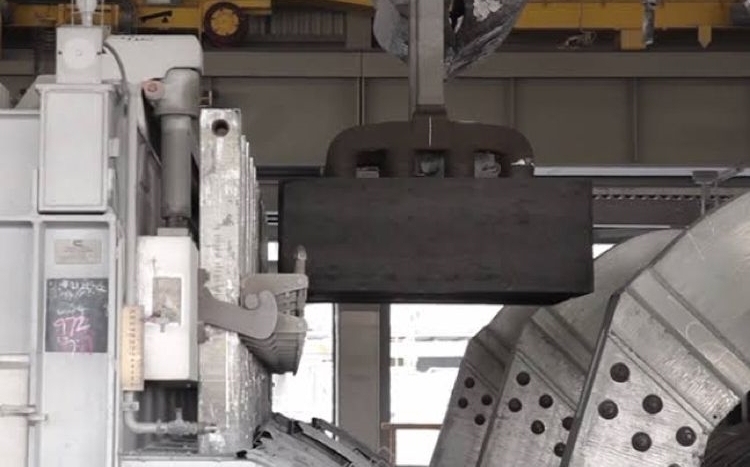

This is metal shaft heavy duty conveyor carrying striped carbon block also called Carbon Conveyor..

This conveyor sends the clean carbon or butts for recycling process.Starting from the crushing of butts through hydraulic crusher mechanism to whole systemically unit of butt crushing unit.

Anode setting operation at Reduction Cells Pot..putting of new rodded anode for producing of first stage of aluminum through electrolysis process.Rodded anodes are getting transfer through over head crane specially design for reduction operation..

In Carbon Anode Rodding plant operation..every assemblies play a role of recycling process..not a single piece of carbon is waste in this production system..Baked and ready carbon block technically called anode in aluminum smelter operation..this is anode stacking operation in Anode Baking Furnaces (ABF) department. standard of anodes storage is very high and systematic through the help of specially design anode stacking overhead crane ..

This machine is called Stem Brushing Machine .Its a specially designed machine used to brush or clean the stem(aluminum rod bar) to remove the dust and other particles.Also to make the surface of rod smooth to avoid any spark when its used in reduction cells pots.

Baked and ready carbon block technically called anode in aluminum smelter operation..this is anode stacking operation in Anode Baking Furnaces (ABF) department.

standard of anodes storage is very high and systematic through the help of specially design anode stacking overhead crane ..

Baked and ready carbon block technically called anode in aluminum smelter operation..this is anode stacking operation in Anode Baking Furnaces (ABF) department.

standard of anodes storage is very high and systematic through the help of specially design anode stacking overhead crane ..

This machine is called Stem Brushing Machine .Its a specially designed machine used to brush or clean the stem(aluminum rod bar) to remove the dust and other particles.Also to make the surface of rod smooth to avoid any spark when its used in reduction cells pots.

This machine is called Stem Brushing Machine .Its a specially designed machine used to brush or clean the stem(aluminum rod bar) to remove the dust and other particles.Also to make the surface of rod smooth to avoid any spark when its used in reduction cells pots.