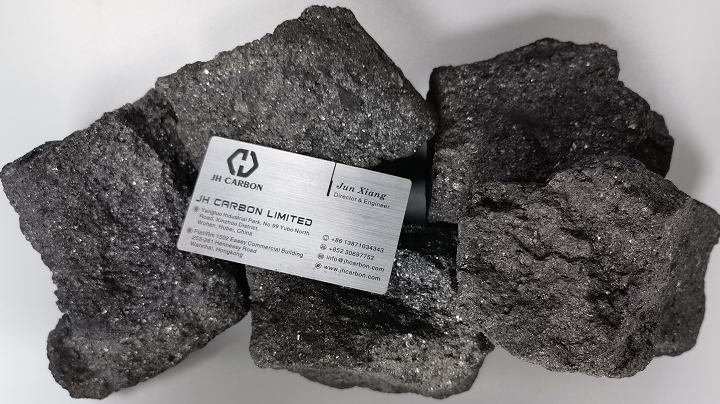

Description

Coke is a major material for the production of iron. Metallurgical coke supplies most of the reducing gas and heat for ore reduction and smelting.

Metallurgical coke is the coke used for blast furnace ironmaking. Since more than 90% of metallurgical coke is used for blast furnace ironmaking, it is often called metallurgical coke. Metallurgical coke plays the role of heating, reducing agent and framework in blast furnace.

Difference between metallurgical coke and foundry coke:Foundry coke is used for smelting iron in Cupola,Compared with metallurgical coke, foundry coke has large size, low reactivity and small porosity.

For details of foundry coke, please visit the website:https://jhcarbon.com/product/foundry-coke/

Browse through the following links for regarding the size on metallurgical coke :

Metallurgical Coke with Size 1-10-30-80mm